Description

CO2 LASER cutting machines & CO2 LASER engraving machines

CO2 laser cutting machines use the energy of the focused beam of light to cut and engrave objects. The focus zone is very small and gives an almost instantaneous evaporation of many materials. The size of this spot focus is usually about a tenth of a mm.

The cut line can be positioned quite accurately in on the piece thus achieving an unprecedented error of the cut of 0.01-0.03 mm.

How to choose CO2 laser cutting machine

To make a good choice the effectiveness and precision of the machine must match the application of your project. This means that corners cannot be cut in costs. It is possible to cut thinner materials with an overpowered laser. But on the other hand, thicker materials cannot be cut by a cheap machine.

One of the factors in growing your business is the reduction in expenses due to breakdowns. This can be achieved by abandoning cheap low-quality laser cutting machines. Also, for the fact that it is extremely difficult to find components as the cheap machines come and go on the market.

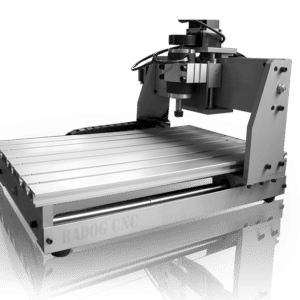

Consequently, it is better to choose Badog CNC premium LASER retrofit machines. The same machines we started with 14 years ago. Our service departments work quickly, but they are rarely called upon. Primarily because our co2 laser machines use proven and reliable technologies.

What to consider in a LASER Cutter or LASER Engraver

- The most important points to consider when buying a LASER Cutter or LASER engraver is:

- The Voltage regulator (needs to supports the required range of supply voltage);

- Swivel and lifting/lowering table (adjustable for layouts of different thickness and shape);

- Chiller (cools the laser tube).

Support and Maintenance for CO2 Laser Machines

Wew have service center specialists that interact directly with customers around the world. Therefore, the client also receives training in the proper laser engraving. Training on cutting with the co2 laser machine. Our clients also receive advice that could reduce the risks to failures in the production chain.

Operating principle of CO2 laser machine

The electricity supplied to the co2 laser tube is absorbed by carbon dioxide molecules. As a result, they begin to synchronously emit in-phase electromagnetic waves in a narrow frequency range that pass through the optical system. It provides focusing at the required radiation distance for laser engraving or cutting. According to the other two coordinates, the positioning of the cutting tool is carried out by an electromechanical system.

During cutting, the temperature in the optical focus of the laser causes the material to evaporate or melt. With CO2 laser engraving on the laser machine, one of the properties of the material changes – color, structure, surface texture, etc.

What can a CO2 laser cutting machine be used for?

This CO2 laser machine is used to engrave and cut plywood, cardboard, plastics, paper and leather

Conclusion

Time-tested protocols make it possible to practically eliminate the likelihood of industrial breakdowns. It is only necessary to consider the material, speeds, and powers. For example, when cutting small workpieces with a CO2 laser machine, engraving should be performed first. This ensures a result that is clean and efficient

The Badog CNC Co2 LASER engraver and LASER cutter is a perfect addition for any shop. It can be easily transported and is easy to use in any shop. The imagination is the ultimate limit to this machine. One you get it through the door of your shop it will give you years of precise clean pieces.

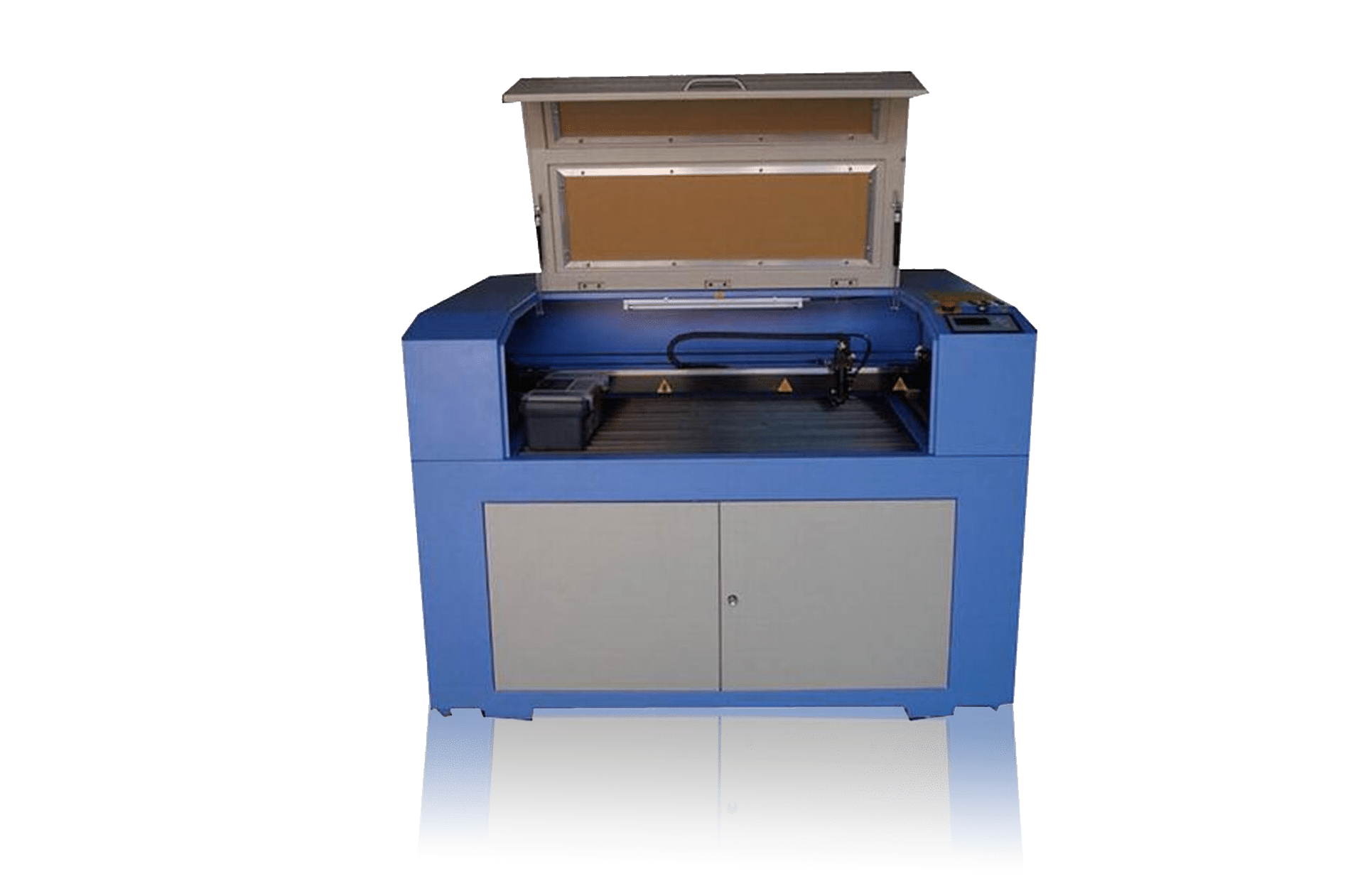

KR960 Laser Engraving Machine

Specifications:

| Machine Description: | Laser Engraving Machine KR960 |

|---|---|

| Working size: | 900mm*600mm |

| Laser power: | 80-100W |

| Laser tube: | Co2 sealed glass laser tube water cooled |

| Engraving speed: | 1-1200mm/min |

| Cutting speed: | 0-400mm/min |

| Repeating location: | ±0.1mm |

| Resolution ratio: | 0.025mm |

| Minimumshaping character: | Letters 1 x 1mm |

| Software: | Lasercut ,Coreldraw and Phototshop output directly |

| Support graphic format: | DST, PLT, BMP, DXF. |

| Up and down work plate: | 50cm height. |

| Interface: | USB |

| Cooling system: | water-cooling and protection system |

| Exhaust system: | exhaust fan and air assist |

| Operating temperature: | 5-40°C |

| Operating humidity: | 5%-95% free of condensed water |

| Gross weight: | 240kgs |

| Package size: | 1420mm*1020mm*1200mm |

Optional Accessories with machine:

1. Rotary device.

2. Auto up-down work table.

3. Inudstry water cooling unit.

4. Red dot.

5. Auto focus.

6. DSP off-line operation with USB flash.

Guarantee & After Sales Service:

1) The machine guarantee is 18 months.

2) 24 hours technical support by email or calling.

3) Friendly English version manual and operation video CD disc.

Application:double color board, plexiglass, glass, bamboo and wood, rubber, marble, granite and tiles, leather.

Reviews

There are no reviews yet.