Swiss company guaranteed Swiss!

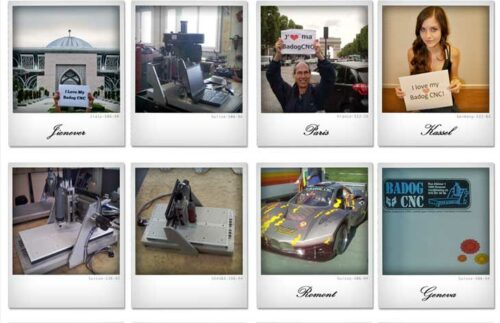

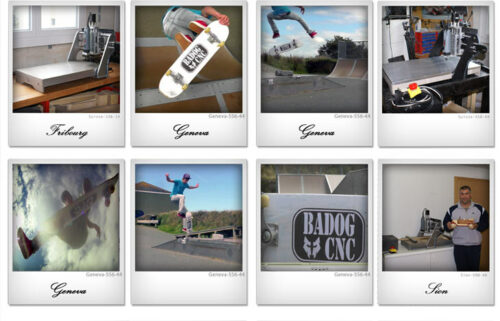

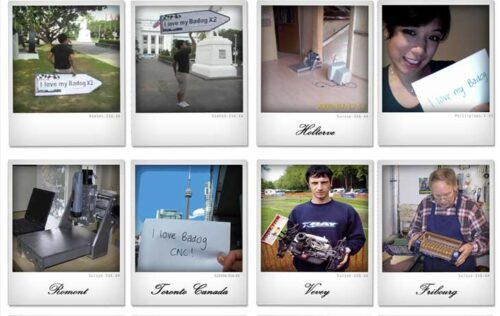

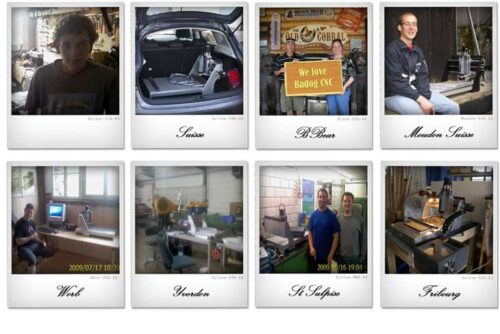

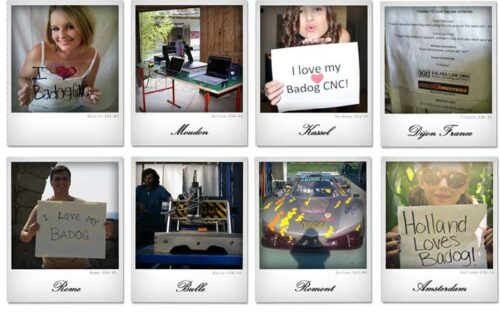

our clients:

Our philosophy

We have built our business while helping our clients to build their dreams by exploiting cutting edge technology used by top manufacturers and designers all over the world to force the balance of power back to where it should be, to the small business and hobbyist.

Since we opened our doors in Romont, Switzerland in 2007 the demand for our products is very high but to ensure quality and a high level of excellence, every Badog CNC is completely hand assembled with precision by an accredited and prize winning Swiss engineer using Swiss raw materials. This philosophy of in-sourcing us to maintain a superior quality without adding the price to our machines. Unfortunately for us, we have a never changed the price of our Badog CNC machines, instead we have found better ways to reduce the costs of manufacturing and remove added expenses to pass this savings on to our clients while maintaining our reputation of excellence.

Our compact, precise and ultra rigid desktop milling machines have been sold all over the world but despite the volume, we are proud to say that each of our Badog brand machines are completely cut and milled with a Badog brand machine. We dare any of our competitors to make that claim!

Our company

Not unlike most of our clients now a days Badog CNC started out in Romont Switzerland in late 2007 with nothing more than a dream, and about 900 francs in the bank account. But armed with their passion and a 15m2 workshop, a small highly skilled elite group of mechanical engineers from School of engineers and architects of Friborg had forged their skills together to envision the impossible Badog Project X. Project X was defined as: To build a self replicating Swiss made computer controlled milling and engraving machine capable of milling plates of aluminum and steel around the same price as the current lightweight CNC engravers on the market.

CNC Milling Machines:

Essentially: To manufacture a high-tech precision, rigid CNC mill / engraver for the price of a CNC engraver.

Early in 2008 Badog CNC had already used up the entire budget and lost about 70% of their workforce and design team. But it wasn’t until late 2008 when the radical policy of no outsourcing was put into place by the CEO of Badog CNC, the company showed its first light of hope. No outsourcing meant that Badog CNC would have to design their own control modules, circuits, software, machines as well as internally control their website, sales, and marketing. The cost of manufacturing the machine was cut by 65% and once the software and infrastructure was created to 80%. The first Badog X2 milling machine was built later that year and was priced 5900.- lower than any other machine in its class in the world.

Badog CNC :

The second machine that Badog CNC had manufactured was the Badog X3 which was purchased internally by Badog. This machine from 2008 to 2012 produced an unbelievable 300 complete machines and produced an estimated 25000 pieces in rock, aluminum, steel, vinyl, and wood, and drilled about 100000 holes. It is still faithfully producing machines to this day.