The new adjustable Badog anti-backlash nuts and blocks history

Since a 2009 ago we have introduced and been using anti-backlash nuts and bearings as options on many of our products and, in turn, have eliminated the need for ball screws and belts altogether on our Badog X brand of machine router. We have been well aware at the beginning that the trapezoidal axis was not the first choice in drive (movement) in order to guarantee a precise CNC machine. We have tried many systems over the years but each drive system had its own unique problem that contributed to in precision. The 2 original options of the ball screw and belts were quickly found to be unusable if we wanted to Assure a rigid machine without free play and still save our customers money in the process. We had to find a solution reliable and secure.

The studied were costly and really didn’t go anywhere for example: we had purchased ball screws from china and Switzerland to compare the difference and the difference was absolutely amazing. The Swiss quality was about 20 times better and didn’t have to be sent over by UPS with a large delay but the price was absolutely impossible to integrate into our machine. This is the difference between quality verses quantity and if we wanted to have a machine that costs less than 6000 but still mill aluminium with precision we needed to eliminate the ball bearings and use a fresh idea. In summary we found that a hobby CNC machine with a ball screw that costs 1400 for one axis from Switzerland would mean that the machine would have to cost double!

When we started to compare trapezoidal axes and balls screws in the same price range, we have found that the ball screws that we tested initially for our cnc machines were up to 20% less accurate than the precision Swiss made trapezoidal axes that we use for our machines to this day. This discovery gave us an advantage on the market and gave us a low cost powerful solution and the capacity of the machine to be maintained.

Now the practical part:

I mentioned the anti-backlash system before in our blogs and many of our clients have asked how it works and it was possible to adjust it. We have worked hard on the idea since March and came up with an adjustable free play anti-backlash nut for our machines that allow the user (not only the dealer) to compensate easily for wear to allow a greater lifetime on our line of machines. So here it goes:

The anti backlash system

The new TRC anti-backlash system and how to adjust for free play in the axes

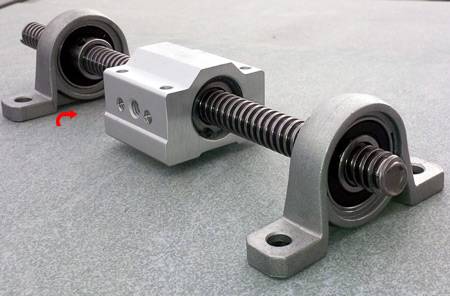

From the image above we see that the system is contained completely in the pillow block (5) with 2 snap rings. The front side is metal (5) and the rear side (5) is a hard slippery polymer (like Teflon) that pre charges the axes movement against the trapezoidal nut. Essentially q plastic pushes the axe against the nut to eliminate the free play. There is an anti-rotation nut (2) installed like a spring in-between 2 other adjuster plugs. (3) The front screw holds the nut in place while the rear (1) screw adjusts for backlash (there is another on the other side)

The adjustment is rather quite simple, in order to eliminate the free play between the axis and nut, you just unscrew the 2 adjuster plugs until they turn freely then tighten them until they block the movement of the trapezoidal shaft. Then unscrew each one out a half a turn and install the blocking nut onto each respective screw.

Never remove the trapezoidal shaft when adjusting the free play.

Done! The Badog machine is built so that access to this adjuster is possible without taking apart the machine, but it is always a good idea to work in the open.

I hope this helps you and if you would like to buy anti-backlash nuts we sell them as a pair in our shop.